Screen Printing

Screen printing is a popular method where ink is pushed through a fine mesh stencil (screen) onto the surface of the product. Each color needs a separate screen, making it best for bold, simple designs with limited colors.

Pros:

- Cost-effective for large quantities

- Produces bright, solid colors

- Works well on textiles, tote bags, and flat surfaces

- Widely available and well-known method

Cons:

- Less durable on smooth or glossy surfaces (can scratch off over time)

- Not ideal for fine details, gradients, or photo-realistic designs

- Higher setup costs for small runs

- Each extra color increases cost

Digital Printing (DTG – Direct to Garment)

Direct-to-Garment printing uses specialized inkjet printers to print full-color designs directly onto textiles like t-shirts, hoodies, and tote bags. The ink bonds with the fibers, allowing for high-resolution, detailed prints.

Pros:

- Excellent for full-color and photo-quality designs

- No setup cost for multiple colors

- Soft feel (ink absorbed into fabric rather than sitting on top)

- Perfect for small runs or one-off designs

Cons:

- Works best only on cotton or cotton-blend fabrics

- Less durable than screen printing for heavy washing/wear

- Slower than bulk printing methods (not ideal for very large orders)

- Limited to flat textile surfaces (not suitable for mugs, pens, etc.)

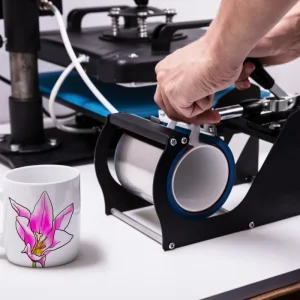

Sublimation Printing

Sublimation printing uses heat to turn solid dye into gas, which penetrates and bonds with the surface material. It’s mainly used on polyester fabrics and coated products like mugs, bottles, and phone cases, producing vibrant and permanent full-color designs.

Pros:

- Extremely durable — design won’t crack, peel, or wash off

- Full-color, photo-quality prints possible

- Perfect for all-over designs (e.g., full-wrap mugs, t-shirts)

- Smooth, no raised edges (ink becomes part of the material)

Cons:

- Only works on polyester fabrics or polymer-coated surfaces

- Not suitable for dark fabrics (best results on white or light colors)

- More expensive than basic print methods for small runs

- Limited to specific sublimation-ready blanks

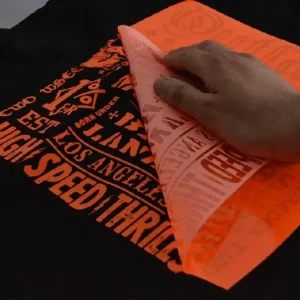

Screen Transfer Printing

Screen transfer printing combines screen printing and heat transfer. The design is first printed onto a transfer paper using screen printing inks, then heat and pressure are used to transfer it onto the product. This method is often used for detailed designs or when direct screen printing isn’t practical.

Pros:

- Allows multi-color, detailed designs with good accuracy

- Can be applied to uneven or difficult surfaces (e.g., caps, bags)

- More durable than standard heat transfers

- Suitable for both textiles and some hard goods

Cons:

- Higher setup cost compared to regular transfers

- Not as durable as sublimation or UV printing on smooth items

- Limited efficiency for very large runs compared to direct screen printing

- Can sometimes leave a visible edge around the design

Pad Printing (Tampo Printing)

Pad printing uses a silicone pad to transfer ink from an etched printing plate onto the product. It’s ideal for printing on small, irregular, or curved surfaces like pens, keychains, golf balls, and other promotional items.

Pros:

- Excellent for printing on curved or uneven surfaces

- Works on many materials (plastic, metal, glass, rubber, etc.)

- Cost-effective for medium to large runs

- Allows for precise placement of small logos or text

Cons:

- Limited print area (not suitable for large designs)

- Not full-color (usually limited to spot colors; each extra color adds cost)

- Durability is moderate — can wear off on frequently handled items

- Less detail compared to digital or UV printing

UV Printing

UV printing is a digital method where UV light cures special inks directly onto the product surface. It produces sharp, vibrant, and durable full-color prints, including gradients and photographic images. It’s widely used on plastics, metals, glass, wood, and coated surfaces.

Pros:

- Extremely durable — resistant to scratching and fading

- Works on flat and some slightly curved surfaces

- Full-color, high-resolution prints (including gradients and photos)

- No setup cost for multiple colors

- Can print directly onto products without extra layers or transfers

Cons:

- Limited to surfaces that fit into the printer (size/shape restrictions)

- More expensive than traditional methods for large runs

- Not as effective on textiles or flexible materials

- Glossy finishes may show fingerprints or smudges more easily

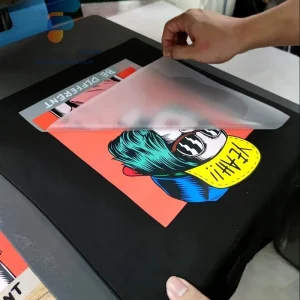

Digital Transfer Printing

Digital transfer printing combines digital printing with heat transfer. The design is first printed in full color (using special inks or toner) onto transfer paper, then applied to the product with heat and pressure. It’s often used for textiles, bags, and small-run custom items.

Pros:

- Allows full-color, photo-quality designs

- Good for small quantities and personalization (names, numbers, etc.)

- Can reproduce gradients and fine details better than screen transfers

- Works on a variety of fabrics and some hard surfaces with proper coating

Cons:

- Not as durable as sublimation or UV printing (may crack or peel with heavy use)

- Can feel heavier on fabrics, especially large prints

- Limited efficiency for large runs compared to screen printing

- Works best on light-colored products; results vary on dark materials

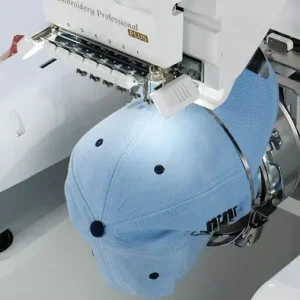

Embroidery

Embroidery uses colored threads stitched directly into fabric to create a design. It’s one of the most premium and durable branding methods, commonly used for uniforms, caps, polo shirts, jackets, and bags.

Pros:

- Very durable — won’t fade, peel, or wash off

- Gives a premium, professional look

- Works well for logos and text

- Suitable for heavy fabrics and apparel

- Can include 3D (raised) embroidery for added effect

Cons:

- Limited detail — not ideal for small text or photo-like images

- Higher cost compared to print methods, especially for large logos

- Each color change increases complexity and price

- Not suitable for thin/light fabrics (can pucker or distort)

Debossing

Debossing is a method where a design is pressed into the surface of a material (like leather, PU, or paper) using a custom metal die and heat. This creates a recessed impression of the logo or artwork.

Pros:

- Elegant, subtle, and professional look

- Very durable — the impression won’t wear off

- Works well on leather, PU, paper, and packaging

- No ink or color required (though foil can be added)

- Adds texture for a premium feel

Cons:

- Limited to certain materials (leather, PU, thick paper, etc.)

- No color unless combined with foil stamping

- Higher setup cost due to custom die creation

- Not ideal for highly detailed or complex designs

Laser Engraving

Laser engraving uses a focused laser beam to etch a design directly onto the surface of a product. The process removes a thin layer of material, leaving a precise, permanent mark. It’s commonly used on metals, wood, glass, and coated surfaces.

Pros:

- Extremely durable and permanent — won’t fade or scratch off

- High precision, even for very fine details

- Premium look, especially on metal, wood, and glass

- No inks or consumables needed (eco-friendly option)

- Works well for personalization (names, serial numbers, etc.)

Cons:

- Limited to one-color (the natural color of the engraved material)

- Not suitable for textiles or soft plastics

- Setup cost can be higher for small orders

- Design visibility varies depending on material and coating (e.g., low contrast on some metals)

Doming (Epoxy Dome Stickers)

Doming involves printing a logo or design on a sticker and then coating it with a clear, durable epoxy resin. The resin creates a raised, glossy, 3D effect that protects the print and makes colors pop. These are commonly applied to keychains, badges, promotional gadgets, and labels.

Pros:

- Eye-catching 3D effect with glossy finish

- Protects the design from scratches and fading

- Can be applied to flat or slightly curved surfaces

- Cost-effective for small, detailed logos

- Quick turnaround compared to engraving or stamping

Cons:

- Limited durability compared to engraving or UV (can yellow or lift over years)

- Restricted to flat or slightly curved areas

- Adds thickness — not ideal where a flush surface is required

- Less premium than direct printing or engraving on high-end items

360° UV Printing (Rotary UV)

360° UV printing is an advanced form of UV printing that allows full-wrap, all-around decoration on cylindrical items like bottles, mugs, tumblers, and pens. The product rotates while the UV printer applies ink, creating seamless, durable, full-color prints.

Pros:

- Allows full-wrap, edge-to-edge printing around cylindrical items

- High-resolution, photo-quality results

- Extremely durable — scratch and fade resistant

- Works on many surfaces (metal, plastic, glass, coated items)

- Great for drinkware, bottles, and promotional gadgets

Cons:

- Limited to round or cylindrical objects that fit in the printer

- Higher production cost compared to pad printing or screen printing

- Not suitable for textiles or flat products

- Some surfaces require a special primer or coating for best adhesion

© 2025 Custom Island Gifts. All rights reserved.